提示:遇到套方案或虚假项目,点击右侧举报按钮进行举报!

举报

项目内容描述

英文项目,替我司德国客户开发。

需求如下:

Modular Approach

The program

shall cover for the Pilot the IEC 62368-1 Heating and Power test for a fixed

set of test equipment. The program architecture shall be designed in a modular

character that allows later the simple adding of new test methods (plugins) and

new hardware (drivers) with low effort (either loading of plugins or simple and

quick compiling of a new build. In addition, the business process has several

repetitive steps e.g. definition of project header data. These generic elements

shall be programmed in such a way that they can be reused for other automation

programs.

Preferably

all value lists, configuration data etc. is available in CONFIG FILES that are

not hard-coded into the source code but can be modified or updated without

recompiling the source code.

For

later versions of the program (not part of PILOT), value lists shall be

accessed from the laboratory DMZ server to allow a central maintenance of

actual data (e.g. List of Laboratories, List of Equipment, Mapping of Equipment

MAC Adress to Network etc.)

Modular Driver approach

The

developed tool shall be rolled out globally in over 60 laboratories. The goal

is, to make use of as much existing test equipment of the laboratories as

possible. Hence the software needs to support several different equipment. We

need to be able to react flexible on new hardware or requests from users to add

more existing hardware.

Preferable drives can be loaded or imported without recompiling the entire

runtime. If this is not possible, it shall be as efficient as possible. Inside

the UI of the software the user has the possibility to select the hardware he

wants to work with.

Program Initialization

When the

program is started the first time, the user shall define basic settings. These

settings can be viewed and modified anytime later via the Program Settings

Default Saving Folder Folder

on the User’s PC where results are stored temporarily

Default DMZ Network Folder Folder on the Laboratory Network

DMZ (Where Results shall be published)

Testing Location Dropdown List of TÜV Laboratories, with filter by Region and Location

For

pilot: Static Data Souce

Single Test vs Sequence of

Tests

The

program shall be alter enhance to support more testing procedures. In the pilot

the tool shall support only Heating and Power Testing, but in later versions

more tests shall be added. The program architecture shall already foresee that

the user can select from a list of available testing procedures which testing

procedures shall be executed and also in which sequence.

Configure and Connect Equipment

/ Drives / Equipment List / Mapping - Consider manual switch steps

After

the testing sequence was defined, the user shall for each of the selected test

methods define the necessary hardware.

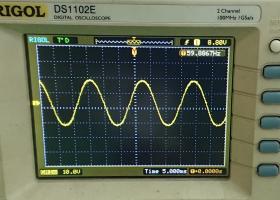

Heating

Test requires:

·Data Logger for Temperature Reading: Temperature in °C on several channels

·Power Supply Reading: Voltage in V RMS, Current in

A, Frequency in Hz,

Setting: Voltage in V RMS, Frequency in

Hz

· Power Meter Reading: Voltage in V RMS, Current in

A, Power in W, Frequency in Hz

Power

Test:

· Power Supply

· Power Meter

Preferably,

each equipment needs to be configured for the whole sequence only once, even if

it’s used in several test methods of a sequence.

Each

equipment shall be selectable from a list of supported hardware

The user

shall have the possibility to select different connection methods (network or

USB)

When an equipment and connection method was selected, there shall be a function

to check if the connection is working.

Some

test Equipment is OPTIONAL. For example, the heating test can be done with a

power supply that can be automatically controller, but some laboratories have

also power supplies that can be only controlled manually.

In case

the user selects MANUAL CONTROLL for Power Supply, the user gets a Pop-Up with

the request to manually set the POWER SUPPLY to the set points of the Voltage

and Frequency defined by the test program. In this dialogue, he can see the

actual readings of the POWER METER and prompt/confirm that the setting was done

manually.

For each

Equipment used, the user shall enter the GTEM EQUIPMENT ID

The user

shall have the possibility to save and recall the equipment configuration as a

template.

Configure Project Header

Information

Once the

configuration is done, the user shall enter the “Project Header Information”

for which test Testing is done

Project

Number & Item Number: one

value in two fields Project Number & Item Number (Number Only)

Test

Report Number: One

value

Test

Sample Number: One

or more values

Name of

Testing Personnel: Windows

Short Name

Not part of PILOT:

in a later Version, the program shall retrieve Project Information from an API

or Webservice

(Enter Project OR Report Number, Get Customer Name, List of Services, Due Dates

and List of assigned Test